MATERIALS

EXAMINATIONS

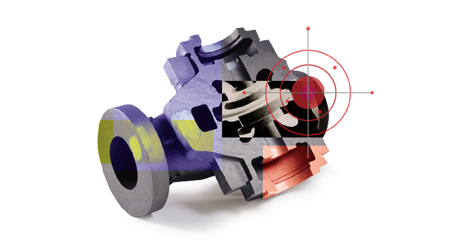

SAFAS manufactures every single casting under quality guarantee system.

Each casting, along the production path, is submitted to destructive tests in order to verify its soundness. In the internal technological laboratory all the other tests are performed on samples of steel, hot or cold, or supplied with the product certification required.

| Chemical Analyses by means of simultaneous quantometers (even portable ones for product analysis) wet method. Mechanical tests

Dimensional inspection

|

Thickness check by means of digital Krautkramer apparatus. Roughness check by means of Hommelwerke apparatus Hardness check by means of various portable and fixed instruments (among which digital Equotip) Residual stress check according to ASTM E 837 Corrosion tests according to ASTM G 48 - ASTM A 262 -NACE TM 0177 - NACE TM 0284. Micrographic check up to 1500x. |

en

en ru

ru it

it